In 1924 Mr O Larsen registered a steel sanitary pail manufacturing company called the Transvaal Steel Pressing Syndicate, Limited (TSP).

Later the company produced milk cans and other heavy hollowware. In 1937, a public company, the Amalgamated Steel Pressing Company Limited

Was formed and took over the entire share capital of the Transvaal Steel Pressing Syndicate, Limited. At the outbreak of the Second World

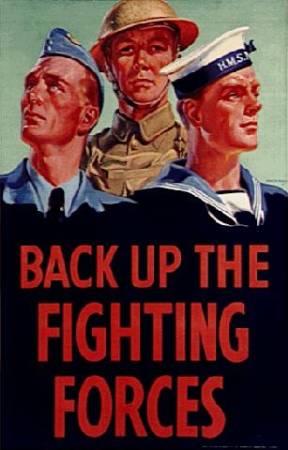

War, the TSP was well established to tackle the many calls made on the firm.

In January 1939, the managing director Mr O Larsen visited a number of similar factories in Europe and made preparations in the event of

War breaking out. For instance he ordered dies, tools and some steel plate for the manufacture of the British Mk 1* / Mk 2 steel helmets.

On his return he had to convince his Board of Directors as to his unexpected / unnecessary expenditure.

The ordered consignments only arrived after the start of the war and thanks to Mr Larsenís foresight, steel helmet production in the Union

Of South Africa commenced in about April / May 1940. There were, however many difficulties and suppliers of raw materials had to be found.

The Iron and Steel Corporation (ISCOR) a newly formed state company, succeeded in record time in producing the right quality of

Bullet-proof steel (manganese steel).

We presume these were to British specifications which called for 12% manganese steel rolled into

Sheets of twenty gauge - that is .036 inch / 0.9441mm thick. Although quite thin, this alloy was able to resist the penetration pistol

Bullet of 230 grains travelling a velocity of 183m/s. This bullet would produce a deep indentation in the helmet but No penetration.

The first three-quarter million helmets were made from ISCOR material.

A number of these helmets were shipped to Great Britain for use

By fire fighting and A.R.P Services during the blitz on London. The weekly production of helmets was between 10 000 and 12 000. Later,

In order that ISCOR could concentrate on other goods, steel supplies from ICSOR were discontinued and supplies were obtained from the

United States.

Production of steel helmets went on almost throughout the war. Occasionally there were hold ups for materials and for conditioning of tools.

Regular shooting tests were conducted to ensure the helmets were up to specification and staff from the Director General Supplies

Inspected each helmet.

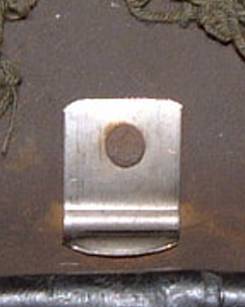

The Transvaal Steel Pressing Syndicate pressed the helmets and trimmed them. Thereafter the three distinctive holes were punched in the

Back rim, one hole in the crown to accept the head liner retaining brass screw and one hole on each side to rivet the chin strap fixings

To. The stainless steel, anti-magnetic channel rim was then fitted and spot welded on the left side of the wearer. The helmets were sent

For painting to Messrs. Herbert Evans & Co. (Pty) Ltd.

Helmets were first painted in the standard UDF green, then a darker UDF green and

Later in a desert sand or those helmets destined for troops in the Italian campaign, in a brown. Jager Rand (Pty) Limited manufactured and

Fitted the head linings and made delivery of the completed helmets to War Supplies.

Once the requirement of the Union Defence Forces had been met (unknown amount but probably in the region of 300 000), production continued

and on 9 April 1945 the Transvaal Steel Pressing Syndicate pressed their one and half millionth helmet.

The excess helmets were supplied

to the Eastern Group Supply Council (EGSC). This council was formed as a result of a conference held in Delhi India between October 25 and

November 25 1940. At this conference delegates from Australia, New Zealand, South Africa, India, Southern Rhodesia, Kenya, Uganda,

Tanganyika, Northern Rhodesia, Nyasaland, Zanzibar, Burma, Ceylon, Hong Kong Malaya and Palestine agreed to a joint war supply policy

which would make use of the existing and potential capacity for war supply of each country. This would prevent duplication of effort and

wasteful shipping from Great Britain. South Africa became the principal supplier of steel helmets to the EGSC. It is estimated that from

February 1941 most helmets made in South Africa at a continued rate of 10 000 a week were sent to the EGSC. About one million,

two hundred thousand helmets were thus exported to the EGSC.

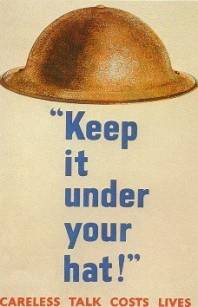

It appears that the use of neck veils was never officially sanctioned but the wide spread use of neck veils in East Africa with the Polo

Helmet, was probably the reason why the TSP included holes for a neck veil. It is not known who instructed the TSP to punch the three holes

in the rear rim, but was probably an officer with East African experience.

Why were neck veils not worn with the steel helmet? By about

September 1941 no further photographs show the use of any neck veils. It is assumed that a Routine Order from this period forbad the use

of neck veils.

BACK TO MILITARIA HELMETS AND HEADGEAR.

BACK TO MILITARIA HELMETS AND HEADGEAR.